What I accomplished this week

- Finished moving into the new office

- Ordered the rest of the equipment and tools needed to complete my research

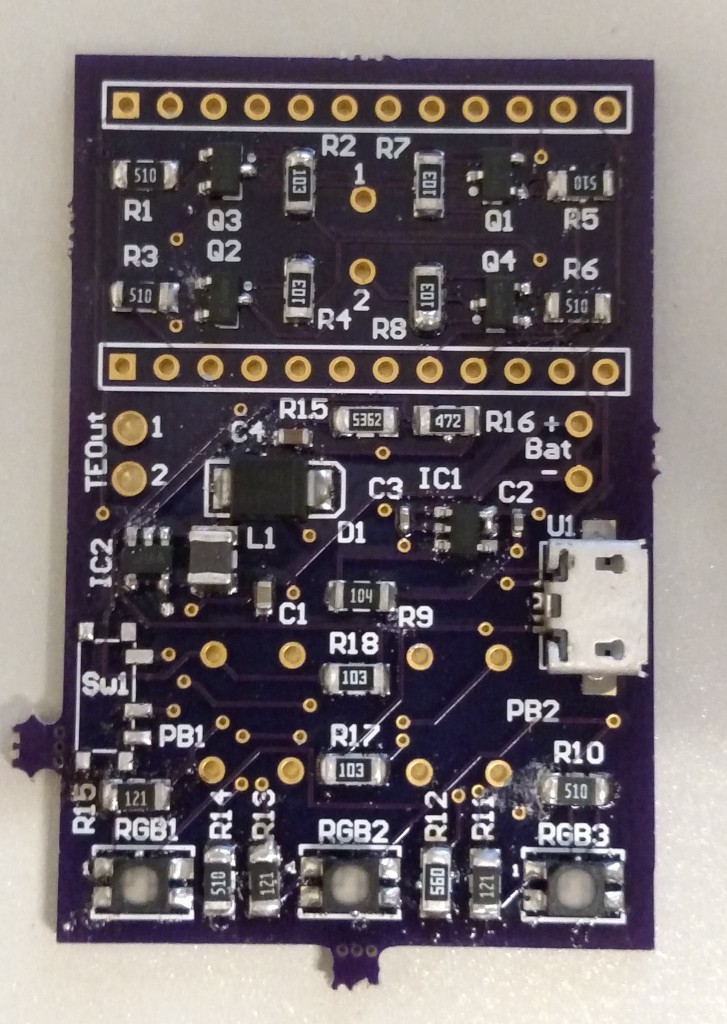

- Populated the PCB with all the surface mount components. The process is as follows

- Apply solder paste to component pads

- Using tweezers, place components onto pads

- Preheat oven to 400 degrees Fahrenheit

- Place PCB in oven and wait a few minutes until you see the components ‘pop’ into place

- Remove PCB and inspect joints. Use solder wick to remove solder if there is excess amounts and/or solder bridges

- Clean PCB of remaining flux using toothbrush and isopropyl alcohol

Problems

- Accidentally snapped a pin off the slide switch which rendered it as useless so I had to purchase more

Next week’s work

- Solder the slide switch, push buttons and headers to PCB

- Test PCB for functionality (Any fried components or smoke coming from PCB?)

- Conduct electrical measurements using multimeter

Below is an image of the board for prototype 1.2