To sum up my work this semester, Professor Ponto has asked me to answer some questions about my project.

1) Describe your final project. What have you accomplished over the course of the semester?

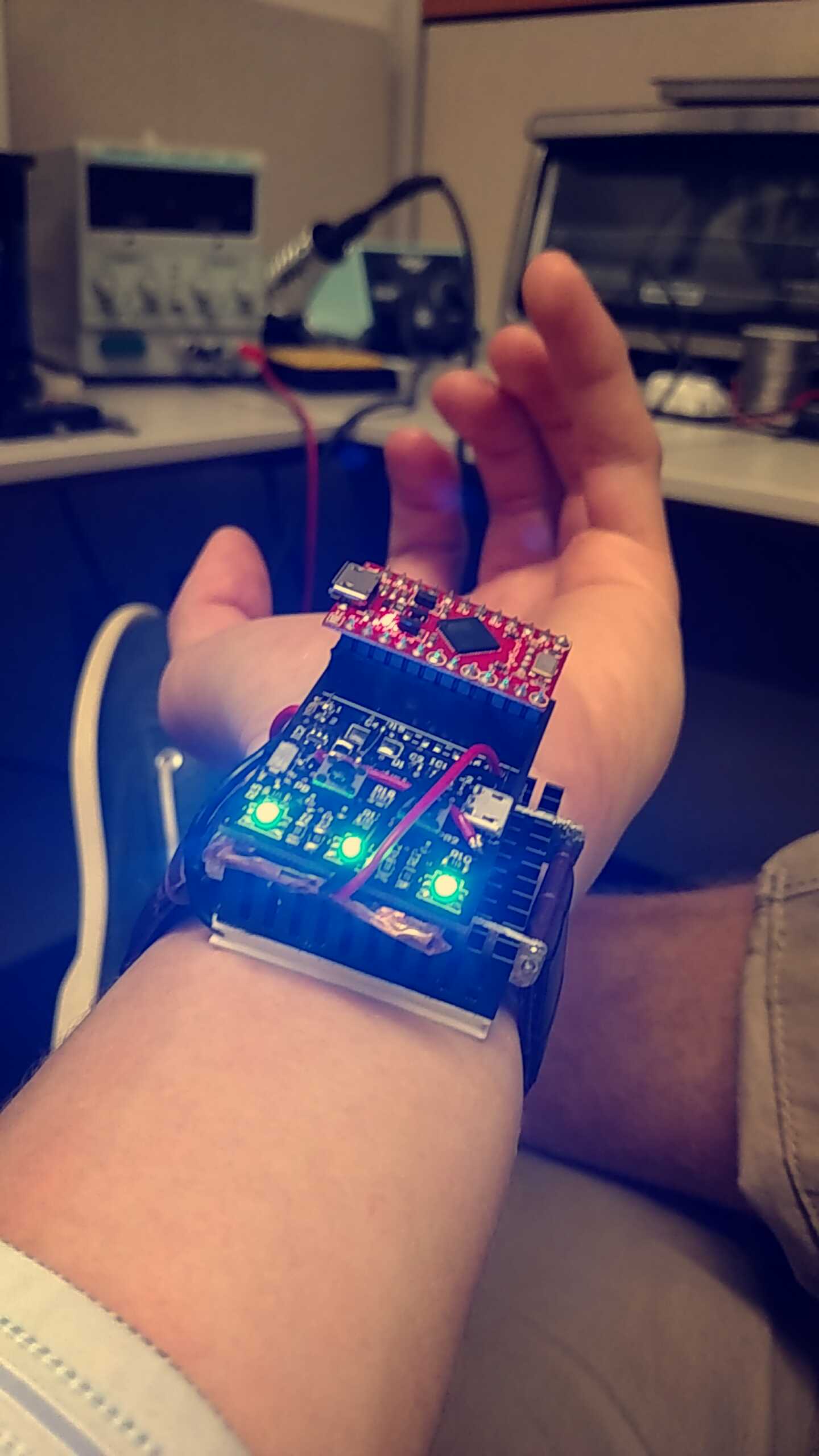

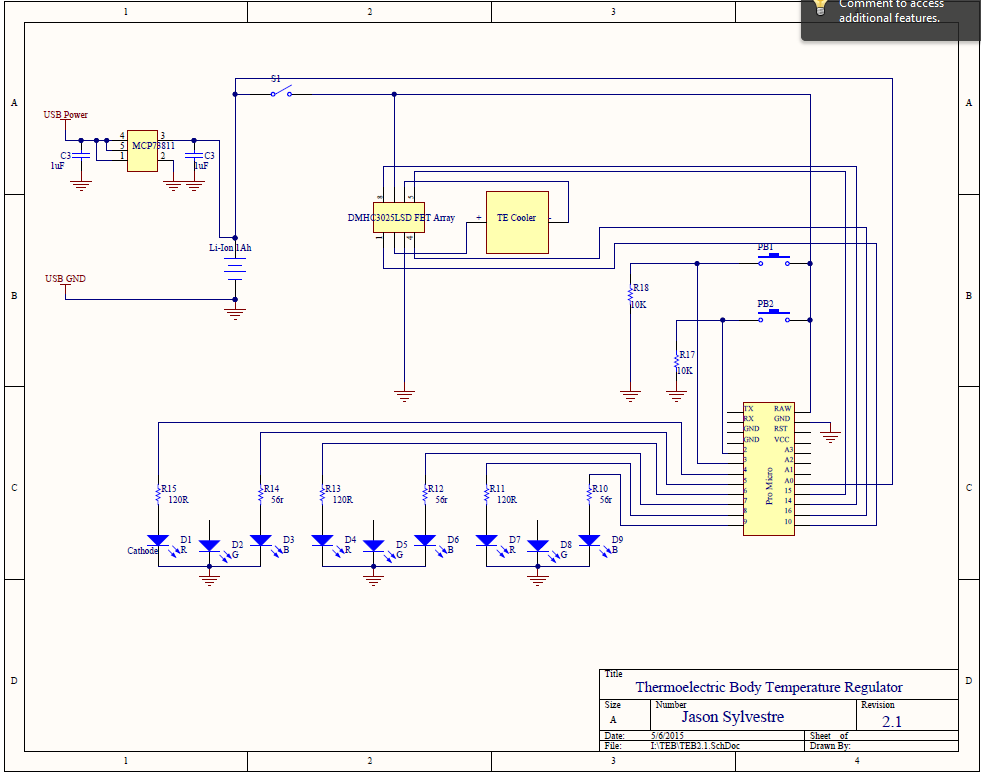

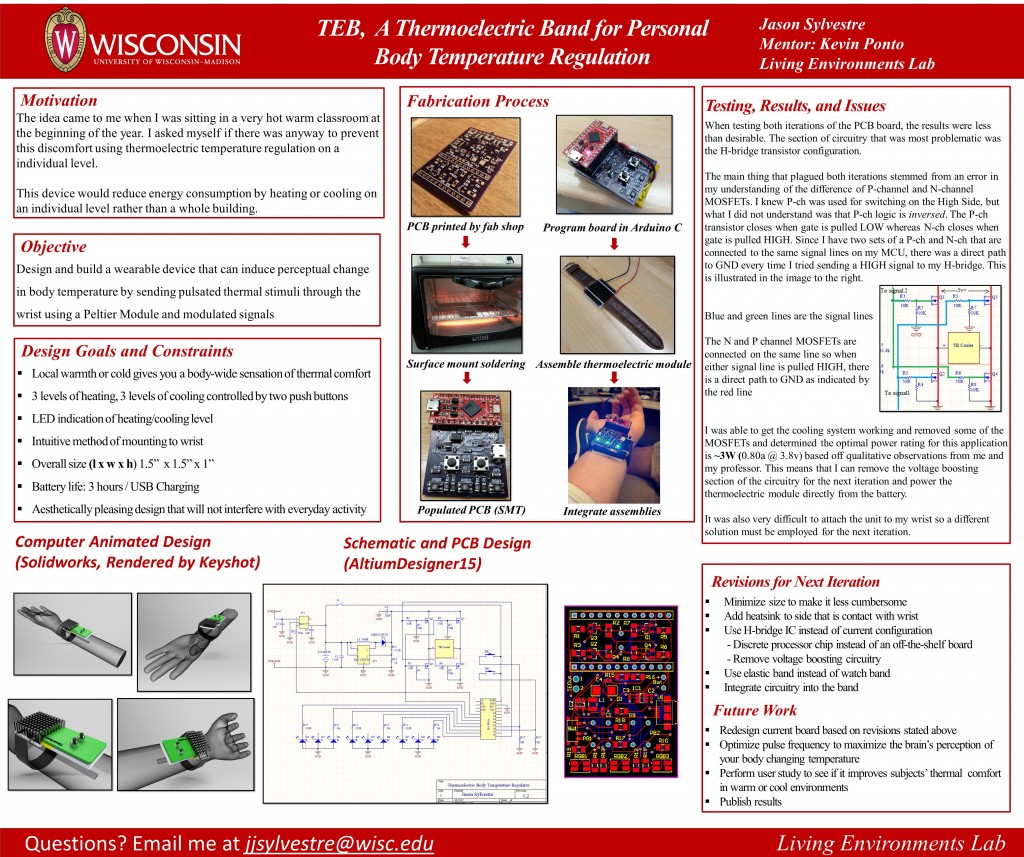

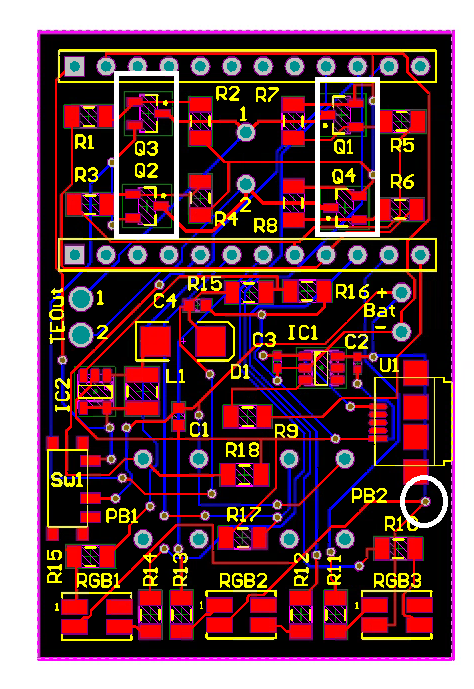

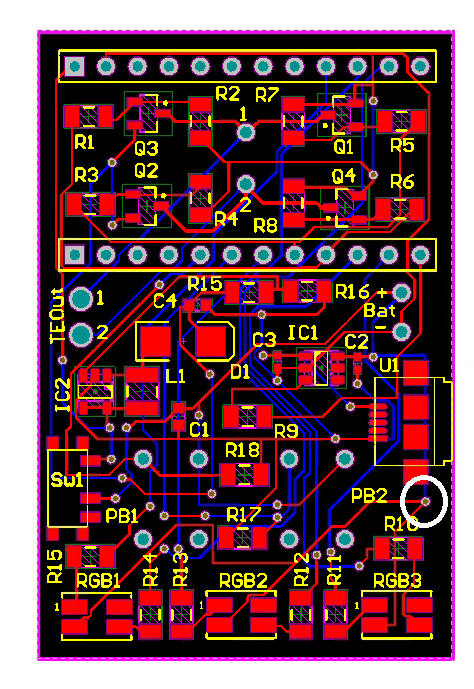

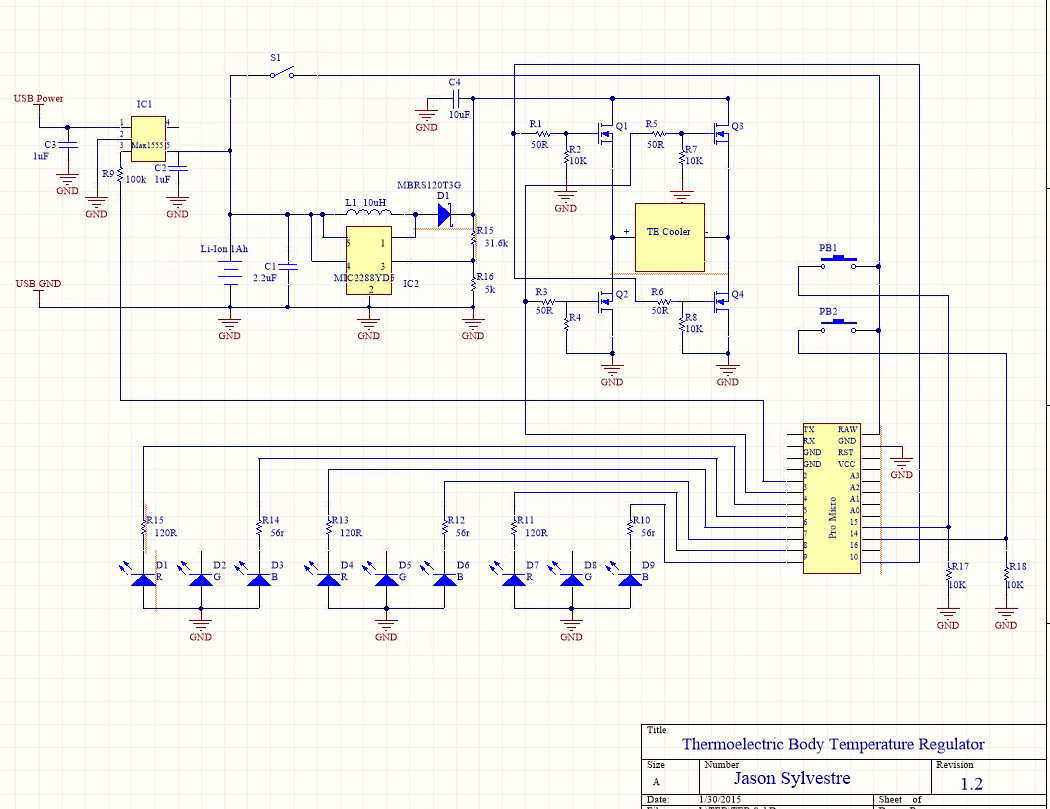

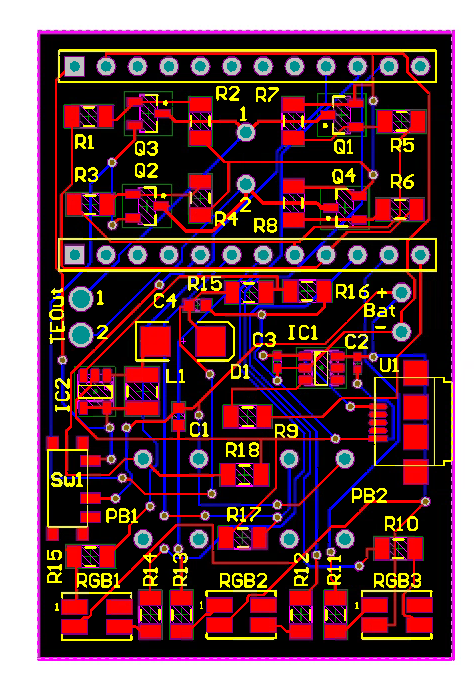

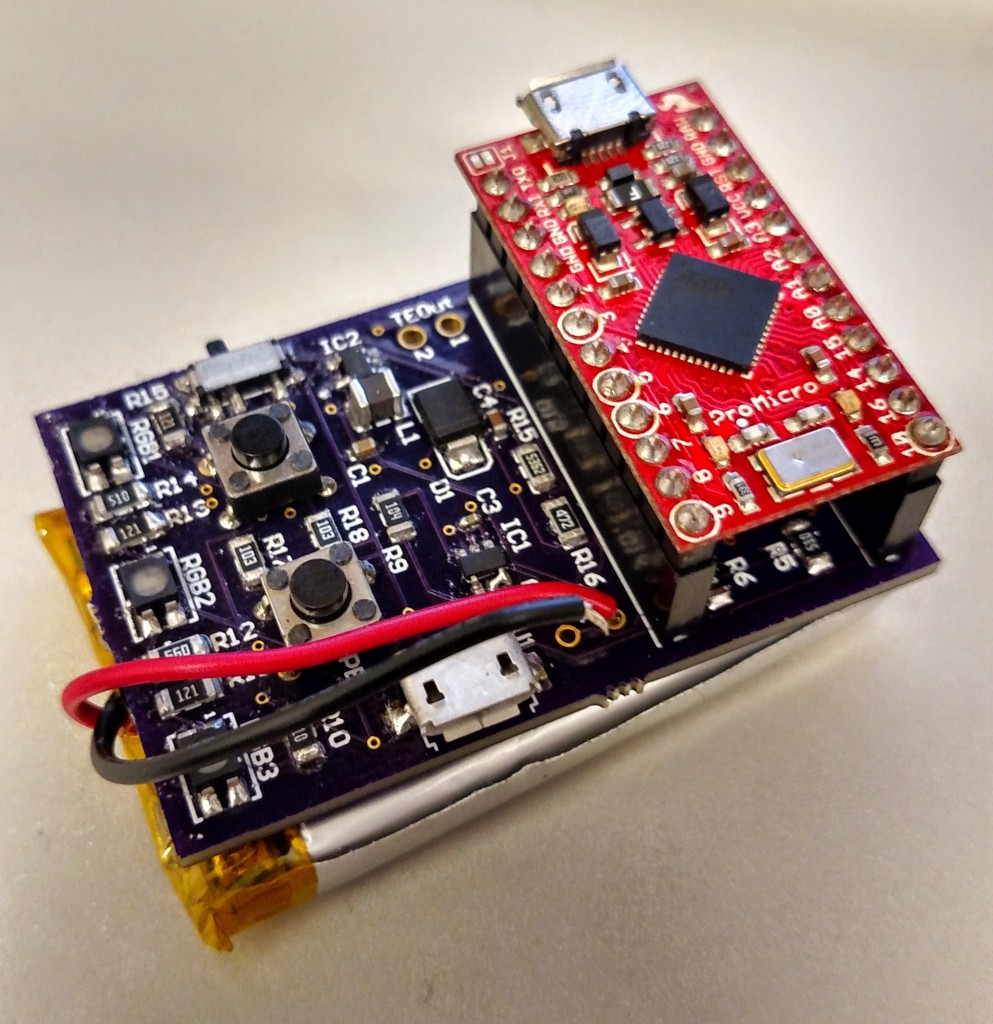

TEB is a thermoelectric bracelet that can be used for personal body temperature regulation. The current prototype uses a thermoelectric module in combination with a microprocessor to send automated pulsated thermal stimuli through the wrist to induce a perceptual change in body temperature. The effect is similar to putting your wrist in cold water on a hot summer day. This semester, I completed prototype 1.2, which was mainly composed of fixing issues that plagued with the first iteration prototype. I had to redesign the circuitry and then also rewrite many aspects of my code to accommodate those changes. I spent the majority of the semester testing and troubleshooting circuitry issues, but after many hours in the lab, I was able to get it working to a point where you can actually feel the pulses of cool stimuli running through your wrist.

2) Describe your overall feelings about the project. Are you happy, content, frustrated, etc with the results?

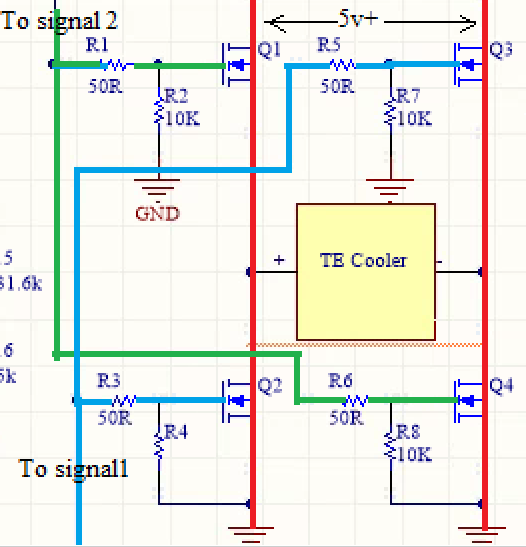

As with any engineering project, there are times of frustration and times of great satisfaction. With this project, it was particularly frustrating to see that the root cause of all my problems stemmed from my lack of understanding in the difference between P-channel and N-channel MOSFETs. This problem really slowed me down and as a result, I did not get as much done as I would’ve liked this semester. However, I did learn a lot about circuit testing and analysis methods because of this and I am glad that I figured out what the problem was

In terms of how well the device worked, I am very happy with its performance. The pulse frequency on the current prototype has by-no-means been optimized, yet it still cooled me down and made me comfortable during the symposium that I presented at. I was impressed with how quickly the the thermoelectric module can heat up and cool down. Still though, the prototype is too bulky and not impractical and requires size reduction in order for this to be feasible.

3) What were some of the largest hurdles you encountered over the semester and how did you approach these challenges.

As stated earlier, the most difficult part this semester was identifying the circuit design flaw that was causing the circuit to short. To solve this issue, I used a systematic approach and tested each subsystem (i.e. voltage boosting section, H-Bridge section, USB charging section, LED section, and Processor section) using various methods and eventually identified that the H-Bridge configuration was causing issues. From there, I analyzed each component in the system to ensure it was soldered properly and that there were no bridges. I didn’t make much headway with that method so I removed individual components and tested it until it worked. Eventually, I found that when I removed one P-ch and one N-ch MOSFET from the board, the circuit worked. From this, I was able to determine my error in design.

4) If you had more time, what would you do next on your project?

Revisions for Next Iteration

- Minimize size to make it less cumbersome

- Add heatsink to side that is contact with wrist

- Use FET array chip instead of current configuration

- Discrete processor chip instead of an off-the-shelf board

- Remove voltage boosting circuitry

- Use elastic band instead of watch band

- Integrate circuitry into the band

Future Work

- Redesign current board based on revisions stated above

- Optimize pulse frequency to maximize the brain’s perception of your body changing temperature

- Perform user study to see if it improves subjects’ thermal comfort in warm or cool environments

- Publish results