Description of project?

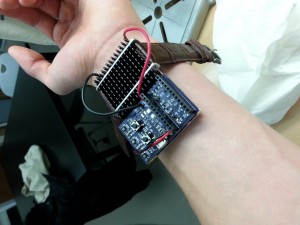

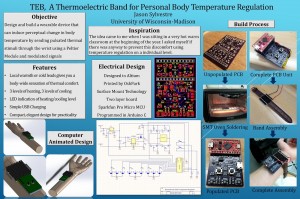

TEB is a thermoelectric bracelet that induces a perceptual change in body temperature so it is essentially a personal air conditioner. Research has shown that when you apply heat to a local part of your body such as the wrist or forehead, your brain perceives it as your overall body temperature changing. An example of this would be placing a washcloth on your head during a hot summer day or running cold water over your wrist when you have a fever. The project harnesses this pyschological phenomenon and it works by sending pulsated thermal stimuli through the wrist using a micrcontroller for the pulse frequency automation and a thermoelectric cooler for providing the heat. Now, there are six levels of heating and cooling so depending on how uncomfortable your environment, you can set the appropriate level using two push buttons and an LED bar for indication.

Overall feelings on your project?

I am quite pleased with how this project turned out given the short timeline we had and the problems I ran into. I felt I was able to quickly and effectively solve those problems where I was able to get a working prototype done by our showcase event. However, I feel there is much more to the project than what I produced with the first prototype so I plan to continue my work into next year.

How well did your project meet your original project description and goals?

With this first prototype, I was able to meet the size constraints I placed so it would be actually practical to wear this device. I was also able to achieve pulsated cooling, but not heating due to a circuitry problem. It actually did cool me down in a uncomfortably warm environment so that’s the main reason why I would consider this first prototype to be a success. I am also still working on ironing out the kinks with the six levels of heating and cooling. Also, a lot of testing is required in order to find the optimal frequencies.

What were the largest hurdles you encountered? How did you overcome these challenges?

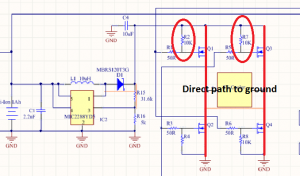

The largest hurdle I encountered was a short that I had on my PCB. It took me about two weeks to locate with the help of Professor Ponto. Originally, I thought it was a problem with the voltage boosting section of my circuitry that is needed in order to drive the thermoelectric cooler. It turns out the problem was not with that section, but rather with the H-Bridge circuitry that enables a voltage to be applied across a load in either direction. If you look at my electrical schematic below, the circled resistors should be pull-down resistors and connect the gate of the transistor to ground so when there is not a HIGH signal, the state of the transistor will not be floating. But, as, you can see, they are currently connected to 5v, which activates both transistors and causes a direct path to ground.

Because I didn’t have enough time to redesign a second PCB by showcase, I made a compromise and removed those transistors so now the hardware was only capable of sending cool pulses. Because I had fried the voltage boosting circuitry earlier, I had to add an external power supply (9v battery) to drive the thermoelectric cooler.

If you had more time, what would you do next?

The first thing I would do next is redesign the PCB and change those resistor connections so they’re actually in a pull-down state instead of pull-up. After ensuring cooling and heating is optimized, I would add a thermal conductor attached to the side of cooler that is in contact with the wrist to dissipate the heat more effectively. Once I reach a prototype that is fully functional, I would like to perform some very scientific user tests with constant variables to see if the device actually makes a difference in improving comfort. If the tests are successful, I will publish my findings in an academic paper.