- What did you do this week?

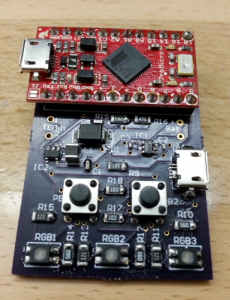

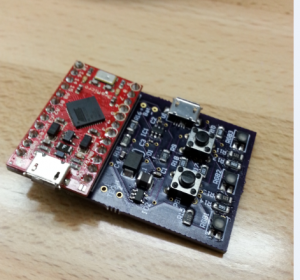

For this week’s work, I soldered all the components onto the printed circuit board and to my surprise everything fit perfectly and went very smoothly. Now in the coming weeks, we’ll see if everything actually works.

- Describe the problems you encountered

One problem I faced was with the USB receptacle. The pins were so close together and I applied too much solder paste and as a result, there was a solder bridge between three pins. This is an easy fix once I get my hands on some solder wick to remove some of that solder.

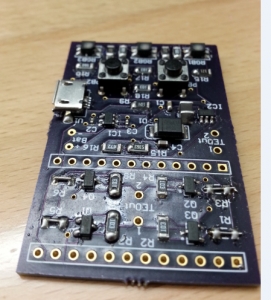

Another problem I faced was that I realized I forgot to order four 56R resistors that connect to the gate of the MOSFETs. Now these resistors aren’t essential to the function of the circuit so I just placed a wire across the resistor pads to close the circuit.

- Describe the successes you had

One success I had was that all the footprints I custom designed fit the components perfectly.

Another success was the method I used for soldering the tiny surface mount components to the board. First, I applied solder paste to the pads of the components. Then, I very carefully placed the devices on the pads using a fine tweezers bent at a 45 degree angle. The solder paste kept the components in place because of its consistency. I then put them in a toaster oven, set the degrees to 450 Fahrenheit and waited two minutes. I had no issues soldering.

- Are you on schedule?

Yes I am on schedule. Now if my circuit has a problem where it will require me to resubmit a new PCB, then I will be behind schedule.

- What do you plan to do next week?

Next week, I plan to perform tests to ensure the board is functioning properly and if it is, then I will be uploading code and will test it using the thermoelectric cooler.