Wisconsin Public Radio has done a story on this class. Click below for the story:

http://www.wpr.org/uw-students-sew-solder-and-sync-build-wearable-computing

Wisconsin Public Radio has done a story on this class. Click below for the story:

http://www.wpr.org/uw-students-sew-solder-and-sync-build-wearable-computing

(Pictures and video will be posted as soon as I get back to Milwaukee, because my stupid phone died.)

Well, that unexepectedly took 12 hours to upload. Sheesh!

1) Describe the operation of your final project. What does it do and how does it work?

As planned, the dress imitates a lightning storm – successfully! Each “cloud” consists of 15 extra bright white LEDs, connected to a single pin on the Arduino. My code is designed to trigger a random number (up to 3 or it blows a circuit, lol) of random pins and then execute the stutter step lightning effect. The brightness and duration of the lightning flicker is also randomized. A flex sensor added under the arm shortens the delay between lightning strikes, giving the effect of increased storm activity when the wearer makes a dramatic gesture.

2) Overall, what are your feelings about your project? Are you happy, content, frustrated, etc.?

Overall, I am extremely happy the the effect. The piece looks almost exactly as a planned and the lightning effect functions perfectly. My one disappointment is that due to losing so much time to technical difficulties, I wasn’t able to sew in as many LEDs as I would like. The gown in it’s current state is much more underwhelming than I intended. Fortunately, this is easily fixed by sewing in the remaining 300 LEDs.

3) What were the largest hurdles you encountered in your project and how did you overcome these obstacles?

Time, time, time. Dying wool takes a lot of time. Making felt takes a LOT of time. Sewing in LEDs takes a lot of time. And all of this was compounded by the last minute failure of my protoboard chips. If I hadn’t lost 7+ hours to trying to troubleshoot that single issue, my final product would have been in a much better state.

4) How well did your project meet your original project description and goals?

As I said above, I am extremely pleased, especially with the program functions. It works exactly as I had hoped and the effect is perfect.

5) If you had more time, what would you do next on your project?

Sew in 300 more LEDs! I’ll be doing this over Christmas, for sure.

here are the circuit guts of the sleeve

closeup of the main circuit board “puck”, surrounded with silicone caulk

here is a detail of the 6 magnets used to have a waterproof connection to the circuit to charge and reprogram

here is a tweet from a SoHE social media guru @UWMadSoHE

1) Describe the operation of your final project. What does it do and how does it work?

My project is a waterproof, swimming arm sleeve that is worn as a motivational tool to help facilitate aquatic workouts. It functions by counting individual strokes, that accrue to light up six successive LEDs to indicate the user how long they have been working out.

2) Overall, what are your feelings about your project? Are you happy, content, frustrated, etc.?

I am overall happy. I need a little bit of break from my project, which I think everyone experiences once finishing something big, but I’m sure in about 3 weeks I will be excited about it again, and I will actually try swimming with it.

3) What were the largest hurdles you encountered in your project and how did you overcome these obstacles?

My largest hurdle was organizing everything that needed to go into the armband. This main hurdle was obtaining supplies online and waiting for them. I was ordering fabric, magnets, LEDs, an accelerometer through three websites and then obtaining silicone caulk and wire in-store. Organizing all of these components was a struggle for me and it did drag my schedule behind, but it overall worked out.

4) How well did your project meet your original project description and goals?

I think my final product 95% matched what I was intending to make. The main component that went into this is my waterproofing design and Nathan’s idea of splitting the USB and having magnet ports. The 5% off was I think the use of a switch to turn the battery off and allow the entire circuit to reset. This was a last-minute design decision that I had neglected, but luckily Kevin helped me through it.

5) If you had more time, what would you do next on your project?

If i had more time, I would make the overall package more streamlined in two separate areas of the circuit design and then the fabric sleeve itself. I would redesign the circuit to include less wire, that is also more flexible to make the entire arm sleeve less bulky. I would also redesign the arm sleeve to accept the circuit better and possible include a clear fabric to see the circuit more clearly. On a second chance, I would also put the 6 magnet USB ports to the outside as a visual element to show off the tech.

Describe the operation of your final project. What does it do and how does it work?

I created a fashionable yet functional scarf. If you are out at night for whatever activity you may be doing this scarf will keep you warm and safe. The scarf has three different functions, meaning three different light patterns you can choose from. You turn the scarf on and off by running your hand over a sensor; with the detection of what number swipe it is, this also changes the pattern of the light display. There are also LEDs that run in a circle simultaneously with the other patterns. These lights are motion activated and will respond to which direction you swipe your hand.

Overall what are your feelings on the project? Are you happy, content, frustrated?

I am really happy with the outcome of my project, a lot of what I learned in the class was applied to the final project, so it was fun to see the final piece come together.

What were the largest hurdles you encountered in your project and how did you overcome these obstacles?

The largest hurdle I encountered would probably be the inconsistency of my motion sensors. They worked sometimes, sometimes didn’t, and would read off very different values at different times. I overcame this hurdle by switching a motion sensor out with a light sensor. Another hurdle I encountered was with the LED wires, I had anticipated that they would be malleable enough to weave into the scarf, and I quickly found out that that was not going to work as the structure of the scarf was too delicate. At this point, I changed focus and approached the application of the LED wires in a different aesthetic direction.

How well did your project meet your original project description and goals?

My project goals changed from the beginning when I realized I was not going to be able to find a product malleable enough to weave into the scarf, other than that, I think my goals stayed pretty consistent throughout the majority of the process.

If you had more time what would you do on your next project?

If I had more time, I would like to find a way to better illuminate the scarf without compromising the comfort of the final piece. Perhaps using two lily pads, one on each end to provide better access to power sources at all lengths of the scarf. I would also like a way to have the product be more customizable to each customer, perhaps giving them many patterns to choose from and allowing them to upload it onto their very own scarf.

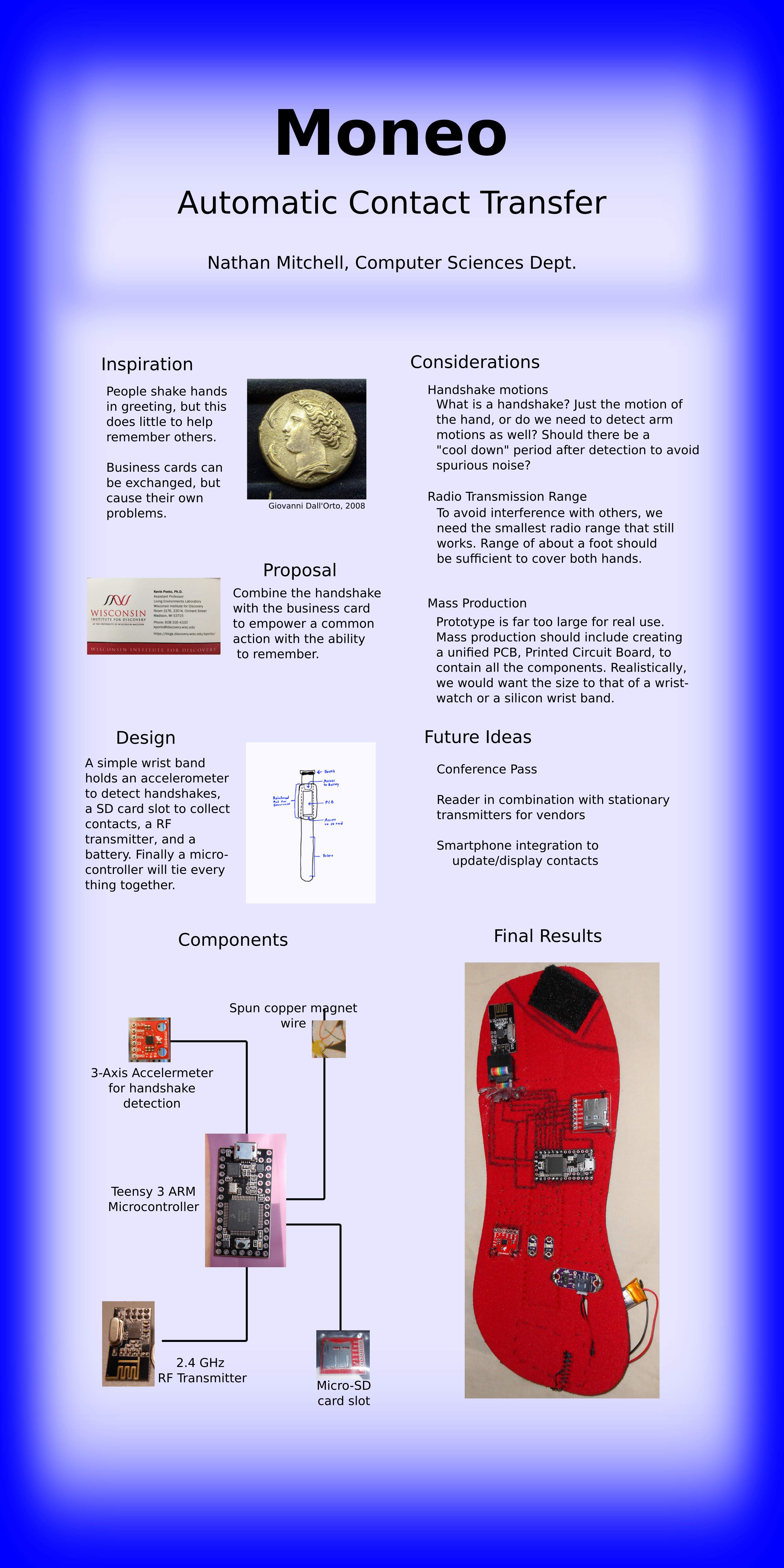

The Moneo project is an electronic business card replacement. Designed to be worn around the wrist, it will store contact information along with possibly a picture in an onboard MicroSD card. Its built-in accelerometer can detect handshakes by sensing oscillation along the Z-axis. When a handshake event is detected, the Moneo will begin a wireless search routine to locate a nearby Moneo which is also in the search state. This is most likely to be the Moneo worn by the person you shook hands with. Once a brief handshake protocol is completed, the two Moneo’s will begin a bidirectional transfer of contact information to each other. Information received, the Moneo will hash the data to check for duplications and, if it is new contact details, store them onto the SD card for later retrieval.

The expected use of the Moneo is at large conferences where one is quickly meeting new people and doesn’t have time or readily available business cards to hand out. Conferences could even provide the devices at registration to act as badges and have them preloaded with the information that was provided during conference registration.

I’m generally satisfied with the outcome given the time constraints and personal funding available. The final product roughly performs all the functions I initially intended, so nothing was greatly sacrificed during the construction period. There were a few bits that I would have liked to look into more, namely getting the range of the transmitters down to about a foot. But I think my own lack of electronics knowledge was a major drawback in this area.

Logistics followed by network protocol programming were by far the biggest problems. Getting parts in and failure to anticipate large delays in shipping almost sank the project. The transmitters were a complete nightmare as they were delayed for about a month longer than the estimated one week shipping time. Combined with the complexity of getting a handshake protocol that was robust to random initiation events, the final result was not as foolproof as I would have preferred. I think if I had another week with the transmitters, I could have made the whole system more stable and reliable overall.

As mentioned above, the project met all the initial requirements, more or less. I think the final range was far too high for real world use, but there wasn’t much I could do about that in the final days. Otherwise, all the other major components were there: Handshake detection, Storage, and Communication. The final assembly worked for the most part, even with the difficultly of using standard breakout boards not designed for wearables.

There are two major next steps that I think are the logical path for this project. The first is better understanding of antenna design and restricting the range of the device such that many Moneo’s can be used in the same area. And the second is miniaturization. Designing a single all-in-one PCB to hold all of the major components will go far in making the Moneo easier to wear, cheaper to build, and more reliable under

mechanical stress from taking it on and off.

1) Describe the operation of your final project. What does it do and how does it work?

The video below shows the LEDs in action (sorry for the cheesy music!):

2) Overall, what are your feelings about your project? Are you happy, content, frustrated, etc.?

I was very happy with my final project. It required a lot of skills that I did not have before taking this class and it was really nice to receive a lot of positive feedback at the exposé.

3) What were the largest hurdles you encountered in your project and how did you overcome these obstacles?

The largest obstacle I faced during this project was that I could not use my code for the pulse sensor with the Lilypad. In order to save time I used the Arduino Uno instead. However, using the Arduino Uno was not planned for in my design so I had to find a place I would be able to conceal the hardware. I ended up creating a pocket for it in the lower back part of the jacket which worked well and can be seen in the pictures below.

4) How well did your project meet your original project description and goals?

My project goals remained the same throughout the project. There were only a few minor changes I made to the design.

I ended up placing the LEDs down the sleeve of the jacket because it is easier to detect moving objects over static objects (assuming that the runner moves their arms when they run) when illuminated at night. This placement of the LEDs should help increase the visibility of the runner.

5) If you had more time, what would you do next on your project?

If I had more time, I would want to create an app that would go along with the jacket. The app would allow the wearer to set the field for the proximity sensor as well as set their target heart rate.

I would have also wanted to do more testing with the pulse sensor. I was not able to actually run when using the pulse sensor so I am curious to see how well it would respond.

1) Describe the operation of your final project. What does it do and how does it work?

Video of just the screen showing an incoming text. Here’s a photo album of the in-progress photos we took over the semester.

We provided an interface that allows the user to continue their current activity in winter (biking,skiing,walking,etc) while acknowledge incoming texts and controlling their environment (signaling) without taking the phone out of their pocket.

We made the glove an interface to information stored in the pocket (where the cell phone usually resides!). This helps keep attention on the surroundings instead of focused on an information device. We anticipate that giving just the minimal amount of necessary information will minimize longer distractions of fiddling with a cell phone.

We ended up using a bluetooth dongle for the Lilypad, and used the Amarino toolkit to implement our communication between the Lilypad Arduino and Android phone. Our code for the android app is up on GitHub. Our LCD was a cheap LCD from Sparkfun. Our Arduino code uses techniques such as interpreting sensor bounce to implement functionality. We used a prototyping perfboard to distribute power and ground to all our sensors and capture the sensor input for routing to the Lilypad. We eventually implemented four sensors in our gloves, two flex sensors and two buttons (one of Quantum Tunneling Composite and the other of compression material).

2) Overall, what are your feelings about your project? Are you happy, content, frustrated, etc.?

I like the the project, I’m really happy with the team working that we had. (lots of new things we learned). We face with a lot problem and bugs in our project but hopefully all of them were solved and prepared the functional prototype. We both learned about Android and Arduino programming, and how to integrate sensors into an embedded system.

3) What were the largest hurdles you encountered in your project and how did you overcome these obstacles?

Our prototype needed a lot of wiring for analog and digital purposes. Embedding those wires were kind of hard and we tried to use a fabric tube over the exterior of the glove to cover those wires. Using a PCB and weaving in conductive thread would have decreased the bulk on the back of the glove, enabling a higher level of dexterity.

4) How well did your project meet your original project description and goals?

The project met all the things that we described (bluetooth, reading/sending texts). We wanted to implement extra functionality, but we believe our final prototype shows how other textual information can be displayed on the glove (emails, tweets, directions) and how sensors can send data to external devices (e.g. send a text, open a garage door, etc).

5) If you had more time, what would you do next on your project?

Shrink the size of the electronic circuit, and explore new techniques for embedding the electronic sensors inside the glove. We concentrated more on the implementation of the technology rather than the final design of the glove, which needs a little bit of work to allow the glove to be easily put on, make the components resilliant to both the elements and repeated use, and to use a portable 5v power source. We also have ideas of interacting with the cell phone (either by typing) or by multiple touch displays mounted on the back of the hand.

Thanks for all the work everyone put into the class!! We both really enjoyed it 🙂

1. What does it do and how does it work?

This dress has led lights on it that pulse to sounds around it. A microphone in the back of the dress picks up sound, which signals the lights to turn on and off making the lights flash to the sounds around it. The middle two panels light up to different volumes than the outer two panels on the dress to mimic the layers in the music or sound surrounding the dress.

This dress has a hand dyed skirt and the wire is hand stitched onto the dress

2. Overall

I am really happy with my project overall. This is the first time that I have ever done anything with programming and my dress turned our better than my original plan. The process was frustrating because I would think that I would have everything programmed correctly and stitched correctly, but when I would plug it in it wouldn’t work. After working through all the programming problems, I am happy with my project.

3. Largest Hurdles

The largest hurdles I encountered was when I found out that using the EL wire was not going to work with my microphone. Once we found out that I couldn’t use the EL wire I had to change my design, but I think it changed for the better. The next largest hurdle was making sure that there weren’t any shorts causing the dress to light up. Lastly the largest hurdle was picking the right volume to have the lights respond to.

4. How well did your project meet your original project description and goals

The final dress is a completely different design from my original description. Originally I wanted to have a dress that had EL wire outlining the silhouette and two different style lines.

As the class time went on I decided that i wanted to have a sensor that would make the dress respond to sound. When I tried to hook up the EL wire up to the microphone, the microphone wouldn’t work. Therefore I had to scrap the EL wire and just use strands of LEDs.

The only thing that remained the same was lights on a dress. I think as the semester went on I realized that I could do more with programming that I thought I could. The final project ended up being more interesting and interactive than my original design so I am very happy with it.

5. If I had more time

If I had more time I would experiment putting lights under the skirt fabric so you would only see the lights when they would light up. I would have also liked to program each panel separately so that each panel would respond to different volumes. I would also like to experiment with ties and bow ties for guys.

here is a nice tatt to visualize how the coordinates are manifested on the athlete’s arm

here is a very nice photo of a magnet successfully nested in the knit fabric with silicone caulk

here is the prototype sleeve for sizing purposes

here is a movie prop from Elysium. That is Matt Damon’s arm and he is modeling and testing the readings of the accelerometer.

here is a circuit completed with the use of the magnet as evidenced by the lit LED

What did you do this week?

I did a lot this week relative to past weeks. I started soldering my circuit, which was really fun. I also patterned and constructed the fabric sleeve “muslin”. With the completed circuit, I tested LEDs and took accelerometer readings based on swimming movements. On Sunday during my lifeguard shift, I took at swim to figure out rough stroke counts per pool length. I really did a lot of little chores that included a lot of little tests.

Describe the problems you encountered.

The hardest thing this week was using the cold heat soldering system. Tonight, I accidentally broke the tip so that was not good.

another thing that i have a problem with is that i am making my wires too long and they are going to be taking up a lot of space.

also, neodymium magnets lose magnetic force when heated so i kind of destroyed a lot of their magnetic hold when using the cold heat soldering gun…..

Describe the successes you had.

I won’t get to all of them, but I found that the magnets conduct electricity. I found my circuit works in that the LEDs function and accelerometer takes accurate readings. I found that the silicone caulk fuses well to both the knit and the magnet. I tested an iron-on tape that should help my magnet openings.

Are you on schedule?

I will finish by Friday.

What do you plan to do this week?

Finish strong and program a lot.

What I did:

This is week was not as productive as I had hoped, but I did make some progress:

Setbacks and successes:

What’s next: