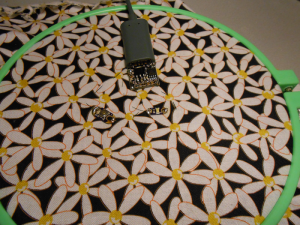

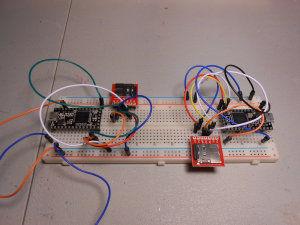

Final Results

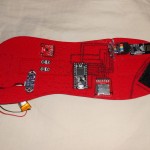

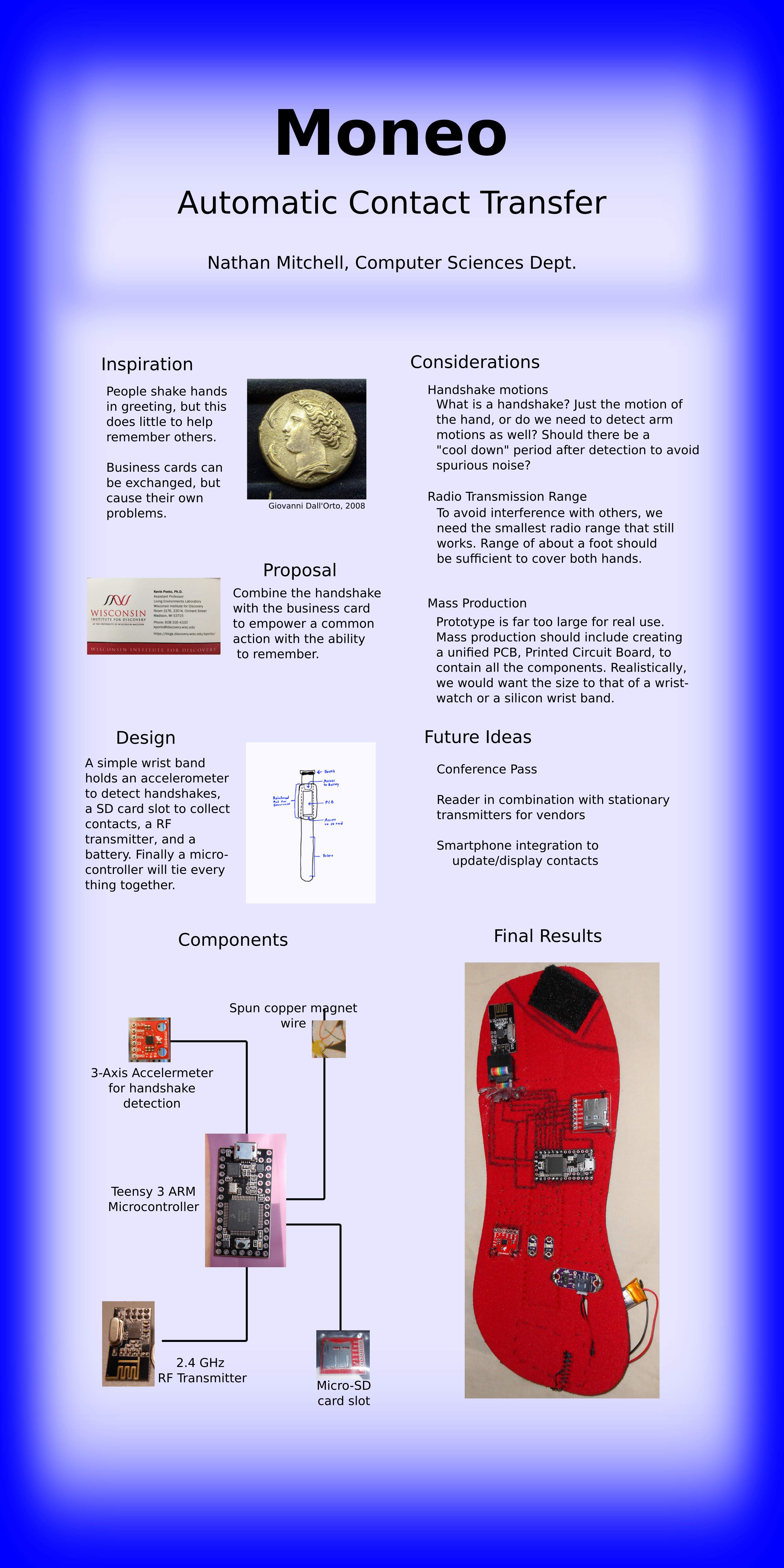

The Moneo project is an electronic business card replacement. Designed to be worn around the wrist, it will store contact information along with possibly a picture in an onboard MicroSD card. Its built-in accelerometer can detect handshakes by sensing oscillation along the Z-axis. When a handshake event is detected, the Moneo will begin a wireless search routine to locate a nearby Moneo which is also in the search state. This is most likely to be the Moneo worn by the person you shook hands with. Once a brief handshake protocol is completed, the two Moneo’s will begin a bidirectional transfer of contact information to each other. Information received, the Moneo will hash the data to check for duplications and, if it is new contact details, store them onto the SD card for later retrieval.

The expected use of the Moneo is at large conferences where one is quickly meeting new people and doesn’t have time or readily available business cards to hand out. Conferences could even provide the devices at registration to act as badges and have them preloaded with the information that was provided during conference registration.

General Post-Project Feelings

I’m generally satisfied with the outcome given the time constraints and personal funding available. The final product roughly performs all the functions I initially intended, so nothing was greatly sacrificed during the construction period. There were a few bits that I would have liked to look into more, namely getting the range of the transmitters down to about a foot. But I think my own lack of electronics knowledge was a major drawback in this area.

Largest Problems

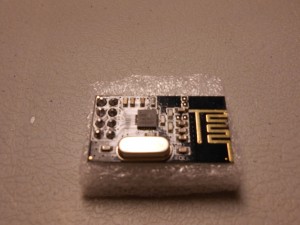

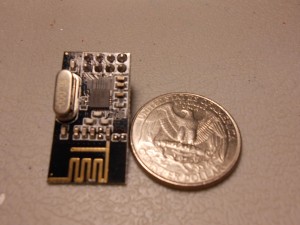

Logistics followed by network protocol programming were by far the biggest problems. Getting parts in and failure to anticipate large delays in shipping almost sank the project. The transmitters were a complete nightmare as they were delayed for about a month longer than the estimated one week shipping time. Combined with the complexity of getting a handshake protocol that was robust to random initiation events, the final result was not as foolproof as I would have preferred. I think if I had another week with the transmitters, I could have made the whole system more stable and reliable overall.

Meeting Initial Goals

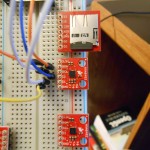

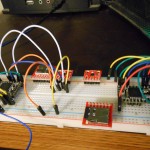

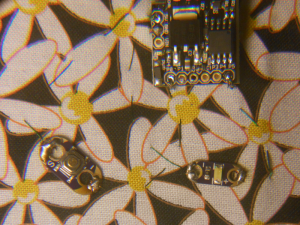

As mentioned above, the project met all the initial requirements, more or less. I think the final range was far too high for real world use, but there wasn’t much I could do about that in the final days. Otherwise, all the other major components were there: Handshake detection, Storage, and Communication. The final assembly worked for the most part, even with the difficultly of using standard breakout boards not designed for wearables.

Next Steps

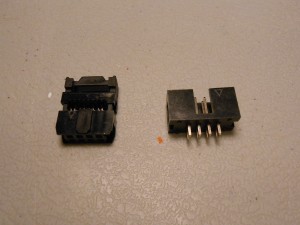

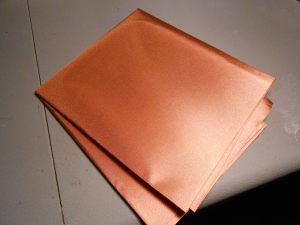

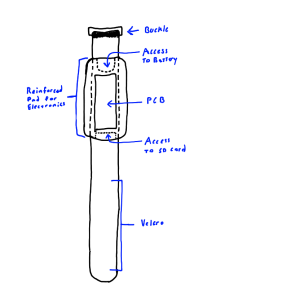

There are two major next steps that I think are the logical path for this project. The first is better understanding of antenna design and restricting the range of the device such that many Moneo’s can be used in the same area. And the second is miniaturization. Designing a single all-in-one PCB to hold all of the major components will go far in making the Moneo easier to wear, cheaper to build, and more reliable under

mechanical stress from taking it on and off.