1. What did you do?

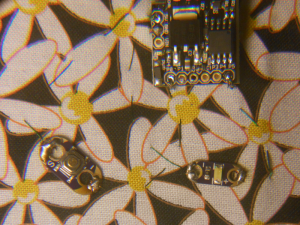

- Received my LEDs

- Received my prefelts and wool dyes

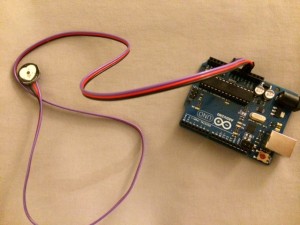

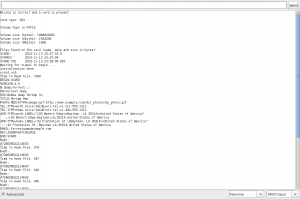

- Tested my LEDs for brightness

- Calculated my LED array

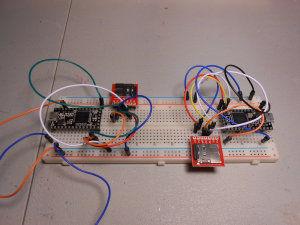

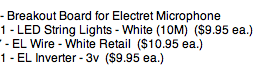

- Ordered my remaining electronics

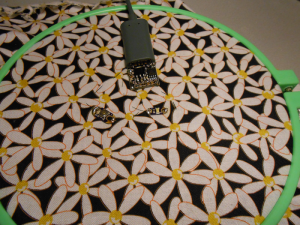

- Planned my wiring scheme

2. Problems

- Nothing major this week *fingers crossed*

3. Successes

- I’ve planned how I can successfully power all of my LEDs and have a solid idea of how to wire and assemble everything.

4. Schedule?

- I’m a little behind, but I think I can still meet some immediate goals

5. Next Week?

- The goal for the weekend is to finish draping the dress, do some dye tests on my roving and then do the actual dying of the roving. This will put me in a position to felt next Friday/weekend.

- The most important task for this next week to complete draping/patterning the dress.

- If the supplies arrive, I would also like to purchase my wool roving and dye it in preparation for felting.