1. what did you do?

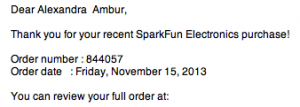

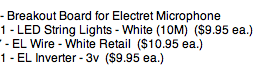

Finally decided exactly what I wanted to do. The lights on the dress will beat to the music or noise around it. I ordered three 3m long el wire and three 10 foot long strings of led lights. This will allow me to program all six strings of light to respond to different volumes of sound.

I ordered all of my supplies. It should arrive by next Friday so I can start programing on Friday.

2. problems

the el wire needs to go through an inverter so it was just an extra cost, but that is minor.

3. successes

I finally ordered everything that i need so i can get going on programing

4. Schedule

next week I will begin programing and continue pattering. I feel behind because i just ordered my supplies but I’m hoping that because I combined this final project with another class I will have plenty of time to devote to this project and can start making better progress.