FInally got to do a bit of work this week.

1) I managed to get the Flora board working on my lab computer, though it is still quite unreliable and needs to be reset all the damn time.

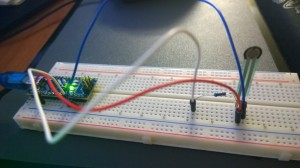

2) To establish I2C communication with my IMU, I had to first make a small modification to the FreeSixIMU library. Apparently in order to get sensor readings from the accelerometer, it is necessary to disable internal pullup resistors on the SDA and SCL pins. FreeSixIMU library did not do this properly for 32u4, which is what Flora uses.

3) Good news end here: data I’m getting from the IMU seems to be junk. While initial readings from the IMU are not always the same, they don’t change at all as I move the IMU around. Also, the device seems to freeze frequently. Assuming the IMU isn’t defective, I suspect wiring issues, some problem with my modifications to FreeSixIMU, or maybe even an issue with serial communication (possibly caused by Flora driver issues.)

My next steps:

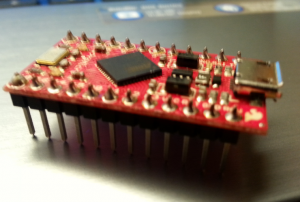

1) I plan to switch back to using the LilyPad for my device. Upon further inspection, I have determined there is no reason whatsoever why either LilyPad and LilyPad Simple should lack support for I2C. Moreover, LilyPad doesn’t use the 32u4 chip and therefore doesn’t suffer from Flora’s annoying driver issues. I suspect the reason why I couldn’t get the IMU working on the LilyPad previously was because of the internal pullup resistor thing, and possibly wiring issues (the IMU is very sensitive to those apparently.)

2) Once I get the IMU working properly with the LilyPad, I will be able to start getting sensor data and implementing my prototype device.