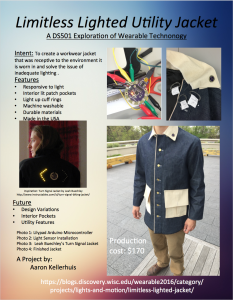

Upload images and videos of your final project and an image of your final poster as a JPG:

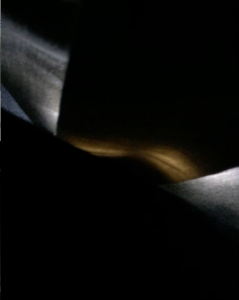

I tried to upload videos but they don’t show up as they are quicktime iPhone videos, so I had to take these screenshots:

light up cuff

interior shot of patch pocket lights

exterior shot of patch pocket lights with flap open

Describe what your project does and how it works:

The design problem my project was intended to solve was the issue of trying to find objects in your pockets in dark environments and the inability to provide light in tight dark areas. By outfitting a denim utility jacket with the lilypad arduino and its light sensor, my garment has the ability to provide light and respond to dark environments. The light sensor is continually reading data of light values to determine whether or not the jacket is in a dark environment. If it is, and if the exterior patch pocket flaps are opened, lights will turn on inside of the pockets to help the wearer find items in the dark. Separate from the light sensor hooked up to a push button, is the LED cuff ring. While in a tight and dark space, the wearer can press the button and light illuminates from the cuff onto whatever the arm is pointed at to provide light in spaces tighter than a flashlight can go into. The patch pockets have 2 LEDs each and function with a switch made of conductive hook and loop closure (velcro). When the conductive hook and loop is separated, the arduino detects the change in the circuit and then asks the light sensor whether the wearable is in a dark environment. If yes, the lights on the interior of the reverse box pleat illuminate the pockets contents.

What are your overall feelings on your project? Are you pleased, disappointed, etc.? :

Overall I am very pleased with how integrated and concealed I was able to make the components by patterning the garment around the requirements of the arduino and the diagram for the connections, all made with conductive thread. I am pleased that I was able to stay consistent with my project pitch and create the wearable that I envisioned and have it functioning! I am disappointed, however, with the cuffs and their construction and the complexity of the technical aspects of my wearable. If I had more time, I would like to develop something more ambitious. All things taken into account, I am satisfied with my work this semester and what I was able to make given my nonexistent pre-knowledge of wearable tech.

How well did your project meet your original project description and goals? :

My project met my original description pretty closely. I had to compromise on the ambitions for my cuffs and their construction and also scaled back to only one light up cuff. My goals of the jacket were met but to varying degrees of success. The patch pockets work as planned but functionally they could be better with a different light source or positioning. Also, with more sampling and tests, I feel the cuff lighting element could be integrated more and function better.

What were the largest hurdles you encountered? How did you overcome these challenges? :

My largest hurdles were in the construction of the wearable. The coding was relatively simple so after it was tried and tested I just had to make sure I made the right connections without interference. Coding wise, I had to work to satisfy the conditional statement to only turn on the pocket lights when it is dark out and ONLY if the pocket was open. The cuffs and their construction is unresolved due to the ridge I had to construct to conceal and mount the LEDs. Originally I envisioned the LEDs embroidered within the cuff with a transparent corded edge on the cuffs to transmit the light without the LEDs being seen at all. Other hurdles would be how I had to wire the components to the arduino, as conductive threads span the entirety of the jacket and utilize the majority of the connections. In the lower photo, this was only after I had wired one of the pockets, the other pocket had to be wired with all 6 connections spanning the distance of the jacket and occupying the remaining arduino ports. Making sure none of the conductive threads would cross to make a short circuit was challenging. Five hours before the show I was having shorting issues causing small sparks and smoking. Tidying the connections and locations of the thread fixed the issue in time.

Another construction consideration that had to be made due to the lining was that all of the components had to be wired beforehand and working. With the shirt sleeve construction I used, the bodice and arm seam is continuous for the outer and the lining. The cuffs had to be applied last because of this order of operations. After everything was tested and assured to function I was then able to close the lining and outer and attach the cuffs. the first few photos show the lining and how no raw edges are showing.

If you had more time, what would you do next? :

If I had more time, I would come up with a more ambitious project integrating more functionality and responsiveness to the environment by using more sensors and have more outputs. Im not sure whether I would continue on a similar path as the limitless lighted utility jacket but I would become more proficient with coding. As a TFD student, my limitations were not in constructing the wearable as much as my limitations were because of my coding inability. It would be interesting if people were forced to partner up with at least one TFD student and one Computer Science major per group. I feel I could have been able to produce something more substantial conceptually with a partner.