Done this week:

Sewed in snaps to the test poncho, along with some neopixels; tested a removable connection to an arduino via alligator clips on unsewn end of the snaps. Works fine when everything’s connected; loss of data or power also seem fine. Loss of ground leaves the neopixels flickering at half brightness, which implies power is then flowing in ways it shouldn’t.

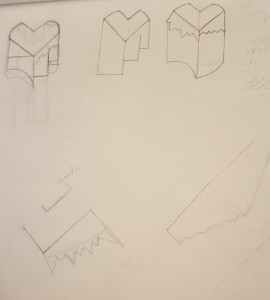

More ideas for the fabric part of the garment:

One: make it modular, as well. Have a base garment that rests on the shoulders, a bit like the current test poncho; snap additional panels in the form of a full poncho, half poncho, or maybe sleeved shirt; mix panels on left and right, or layer multiple; each panel runs a different effect when plugged in, or is driven by an attached shell.

(Also, new terms: panels are modular fabric bits; shells are modular plastic bits.)

Two: add a bunch of RGB LEDs (neopixels?) diffused by plastic plates. How large a region a single LED can cover determines cost, which is the chief obstacle. Need to test this; maybe a good first panel module.

Some new hardware arrived over the weekend: a trinket and raspberry pi. A final (hopefully) order of a few other things is pending, including more magnetic snaps.

Issues:

Nothing exploded when testing lost connections, but I should give more thought to how I can allow power only when everything is well connected. Adding modular fabric panels adds more points for this kind of failure. Adding a power switch and instructions to “power down when removing modules” is easy, but unsatisfying. Any thoughts on this?

A plan for the next week of work:

(3D print, design) Iterate on shell designs.

(software) Build a trinket I2C slave.

(design) Decide what modular fabric panels will look like and do; decide if maybe I should scale back to just one.

(3D print, sew, design) test LED diffusion using plastic plates under fabric