Done this week:

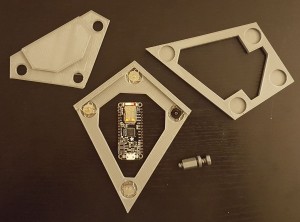

Iterated on shell design. Test prints can be seen above; I think the final version is all planned out, but still needs to be printed.

Scaling plans back to fit into time left. This is mostly triage just now — prioritizing the essentials.

Issues:

It takes a fair amount of time to 3D print things, but it takes a lot of test prints to get a feel for material weight and strength, and just generally what works. For example: friction fit parts work a little strangely due to striations in the print (due to the layered printing process), but I was surprised to find that I can make threaded nuts and bolts quite well. In the next (hopefully final) version, a lot of things will be held together with thumb screws.

A plan for the next week of work:

First:

(3D print, design) Finish the main Shell, then adapt to smaller shells.

(design, fabrication) Find diffuser for in-fabric LEDs; failing that, decide on alternate design.

Maybe into the weekend:

(design, sew) Decide on design, get fabric for, and start making the final poncho.

Then:

(software) Build a trinket I2C slave. Build sub-modules that change behavior of the garment when attached.