What I accomplished this week

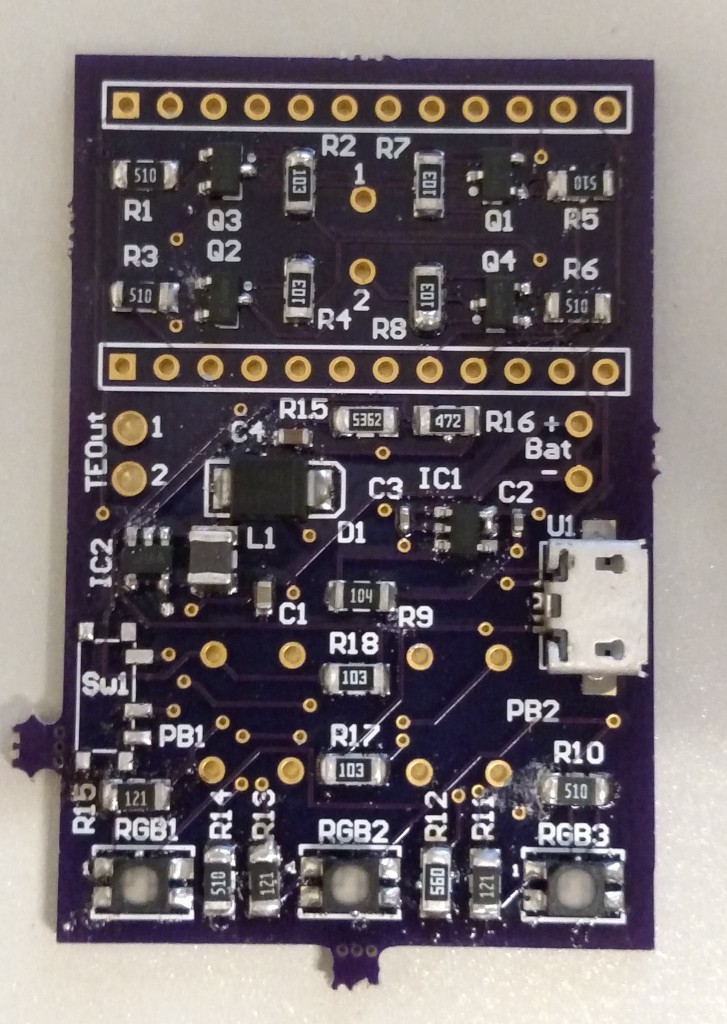

Due to copious amounts of schoolwork and being ill, I did not accomplish as much as initially planned for this week. I did receive the final components needed from Digikey to complete the process of populating board (SMD slide switch, push buttons, and female sockets for the MCU), which I was able to do without any major issues.

Problems

When soldering the slide switch, I noticed the pad spacing for the switch layout was slightly off. I was still able to soldering the switch to the board without a problem, but the spacing should be adjusted for the next iteration of the PCB.

There are also small protrusions from the bottom of slide switch that were not accounted for when designing the PCB. For this iteration, I just used a fine Hobby knife to cut these protrusions off the switch, but holes will have to be added to the next PCB design to accommodate these protrusion.

Next Week’s Work

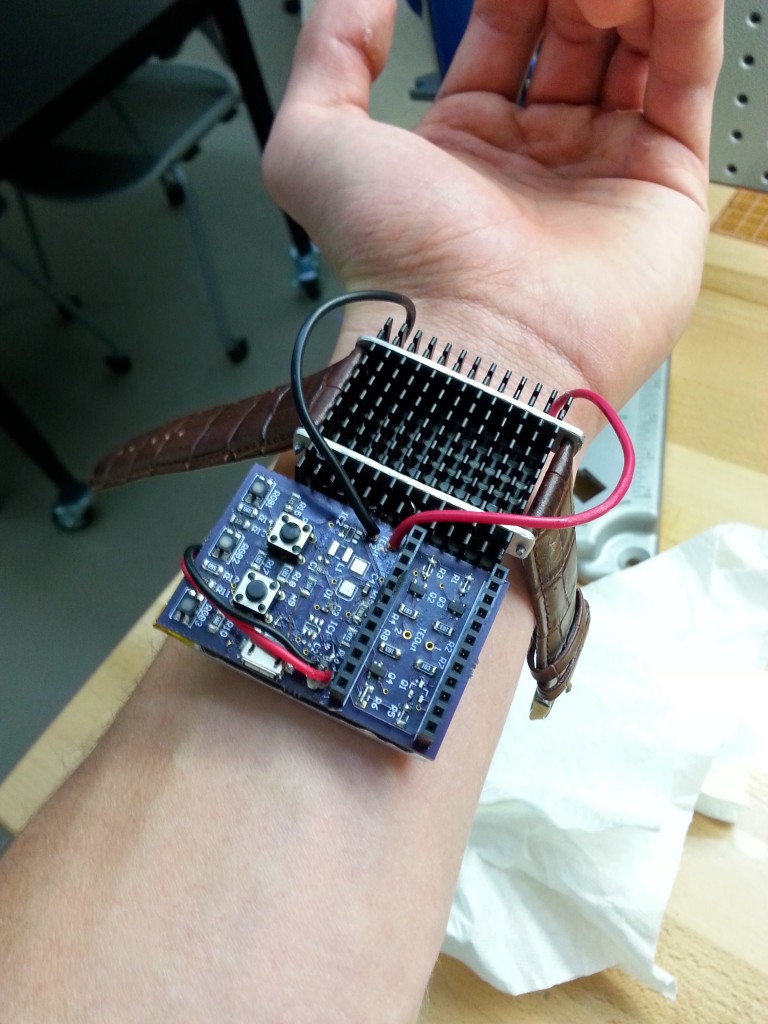

This next week, I would like to test the board to see if it is functioning properly and doesn’t fry any components when you power it uplike the last one did. The main concern addressed with Iteration 1.2 of the PCB was the H-bridge section which is responsible for enabling the voltage to be applied across the thermoelectric cooler in either direction. If it is does work without issue, then the next step will be to start the process of rewriting the code to utilize the hardware interrupts.